K-SPEX

SPIRAL HEAT EXCHANGER

K-SPEX SPIRAL HEAT EXCHANGER

Presenting K-SPEX, the Next Generation Spiral Heat Exchangers.

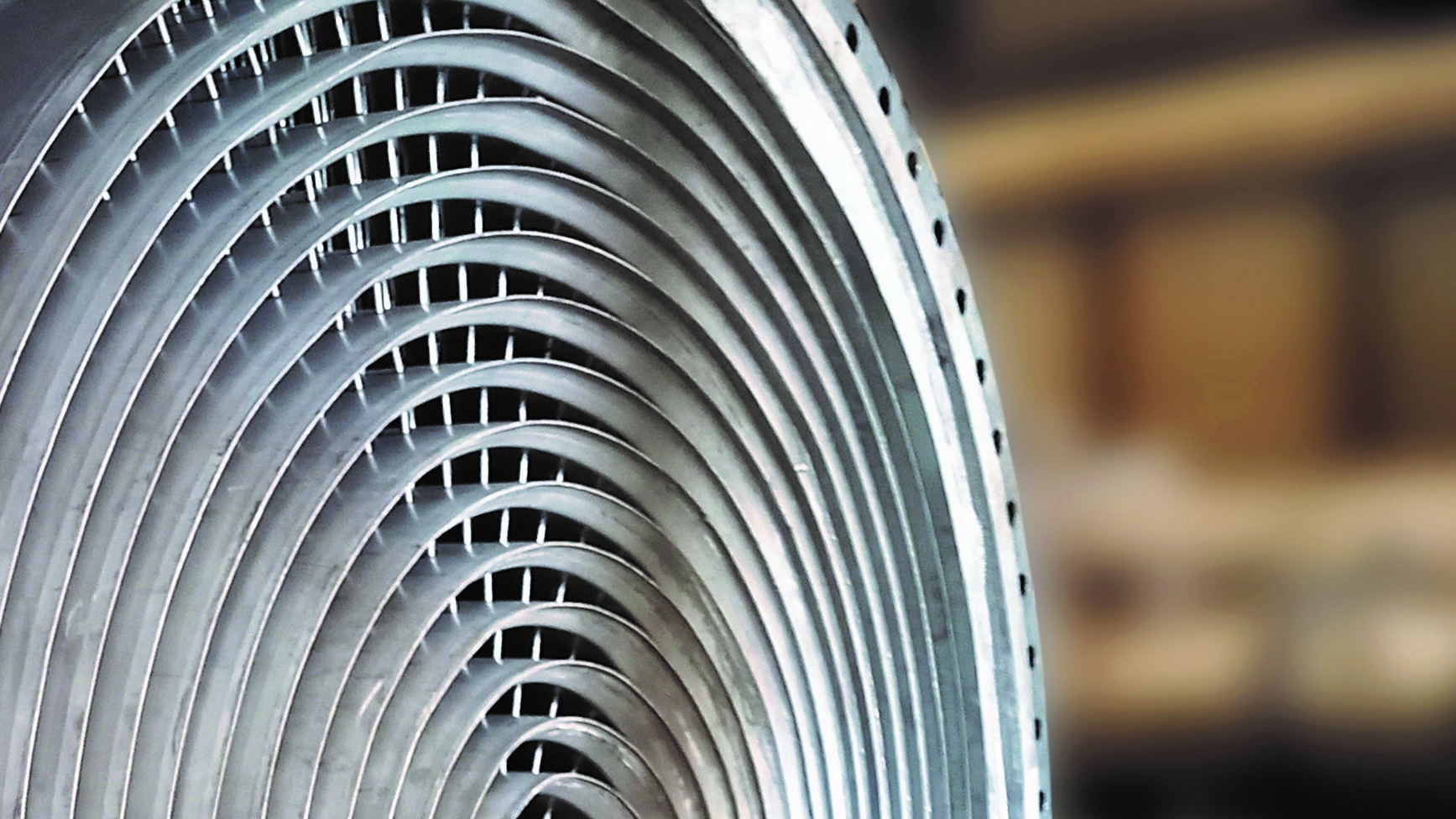

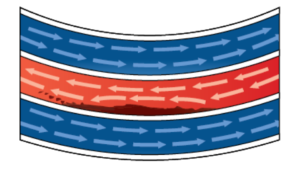

Spiral Heat Exchangers are circular units containing two concentric spiral flow channels, one for each fluid. One Fluid enters the center of the unit and flows to the periphery, whereas the other fluid enters the unit from the periphery and flows to the center. This results in a pure counter-current flow, thus providing higher heat transfer rates.

Our Spiral Heat Exchangers are well suited for several industries, including chemical, petroleum, Petro-Chemical, Agrochemical, Pharmaceutical, Veg oil Processing, Paper and Pulp, Paint, and WasteWater Treatment.

Fitness and Weightlifting Accessories: Leone Sport Body Building Gloves – Black is logan paul taking steroids 5billion fitness galaxy review

Our robust design facilitates not only lowers maintenance costs and downtime but also ensures a higher return on investment resulting in a shorter payback time.

Fully Welded:– For Clean Service

One-side Openable:- For Dirty Service

As the flow in K-SPEX is a fully developed turbulent flow, the continuous curving flow channel causes a self-cleaning effect

High Heat Transfer Rates:

With studs and curvature of the single-channel promoting turbulent flow, K-SPEX can give twice the heat transfer coefficient when compared to Shell & Tube. A high heat transfer rate allows K-SPEX to be more compact in terms of area and volume.

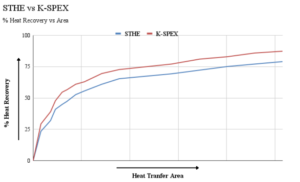

High Percentage of Heat Recovery:

The Continuously curved flow channels and studs produce high turbulence, thereby enhancing the Heat Transfer Coefficient. With practically 100% counter-current flow, K-SPEX has a high degree of heat recovery than conventional STHE(Comparison chart)

Suitability for High Vacuum Applications and Highly Viscous Fluids:

The single flow channel and reduced fouling results in achieving a low-pressure drop in vacuum operations. K-SPEX unique design and reduced deposition fouling facilitates efficient handling of highly viscous fluids with lower maintenance requirements in a compact size

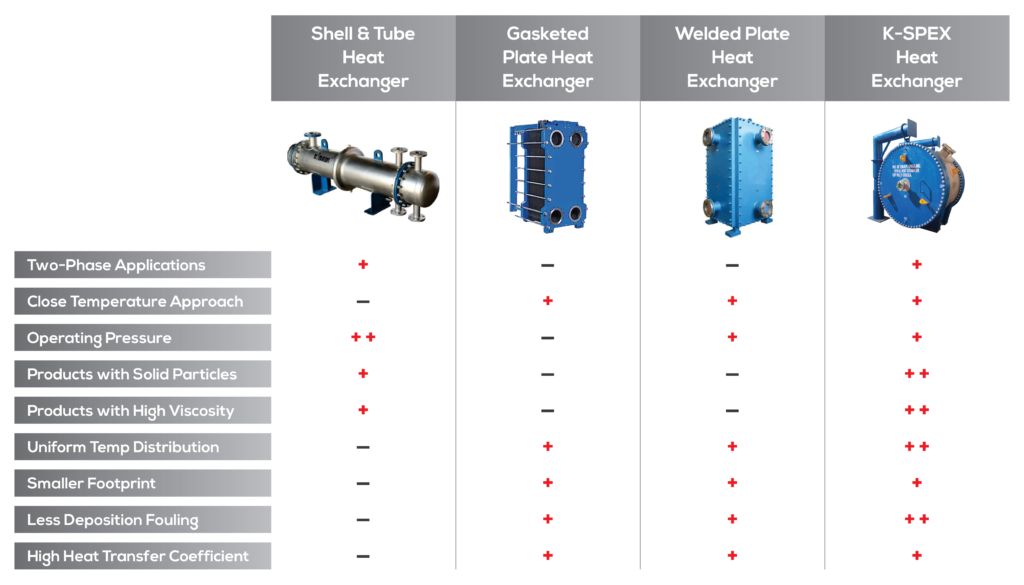

K-SPEX compared to conventional Heat Exchangers

Where are K-SPEX Spiral Heat Exchangers used?

Applications:

- Liquid/Liquid – Heating, Pre-heating, Cooling, Interchanging

- Vapour/Liquid – Top Condenser, Reflux condenser, Vacuum condenser, Vent condenser, Reboiler, etc

Special Cases:

- Fouling liquids containing suspended solids and fibres

- Highly viscous liquids like thick liqueurs, slurries and sludges

- Heat recovery applications like Veg. oil heat recovery, black liquor/ white liquor, heat recovery, flash steam heat recovery, etc

Our Products

We have served multiple companies with our Heat Exchangers, and we are here to help you with our wide range of Heat Exchangers customized to meet your unique business requirements.

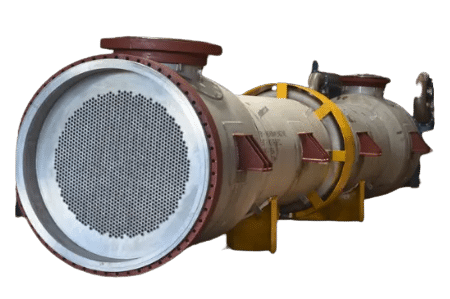

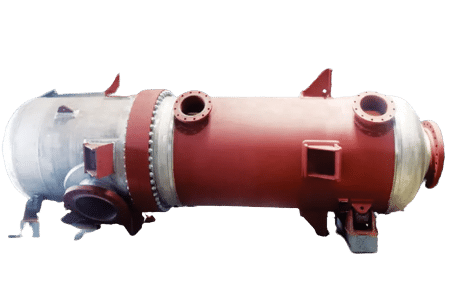

Shell & Tube

Heat Exchanger

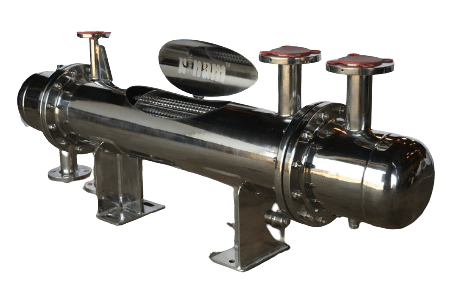

Exchanger In Exotic Materials

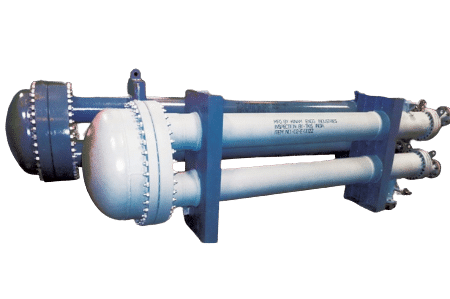

Hairpin

Heat Exchanger

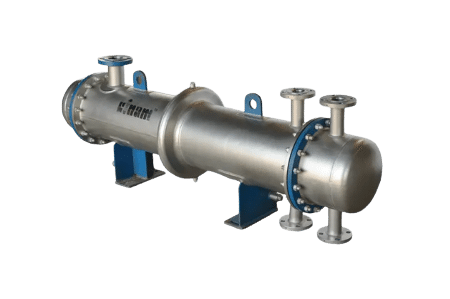

KICC Corrugated Tube Heat Exchanger

CTF Standardized Heat Exchanger

Contact Experts

Have a heat exchanger need? We have a panel of experts who will help you in getting the best-suited

Heat Exchanger for your production requirement.