Why are Corrugated Tube Heat Exchangers cost-effective?

KICC offers up to 30% savings on initial capital investment

The fact that a heat exchanger can save up to 30% for its users is enough to bring attention to this new technology and process.

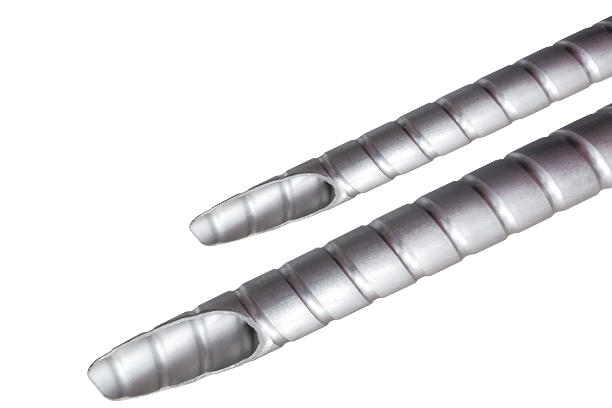

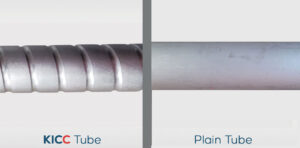

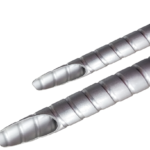

Corrugated tubes are improved versions of plain tubes. Technically, a corrugated tube heat exchanger is produced by indenting a plain tube in a helical pattern without any thinning of the wall thickness or the development of stresses in the tube.

A picture is worth a thousand words. The visual aid below is designed to understand the difference better.

Corrugations on the corrugated tube make a BIG difference.

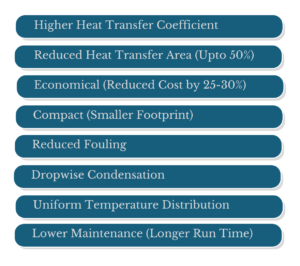

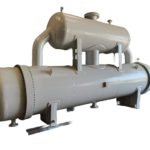

KICC Corrugated Tube technology has the potential to reduce the required heat transfer area by 50% as compared to conventional plain tube heat exchangers.

Due to this benefit, eventually, nearly 30% of initial capital investment is saved for the user, making KICC Corrugated Tube Heat Exchangers ‘The Most Efficient Condensers’. Applicable for diverse industries, it is a critical component that reduces fouling, increases higher heat transfer coefficient as well as saves space due to its smaller footprint.

The proprietary brand KICC is Kinam’s flagship product and is a result of:

- Kinam’s ongoing research and development, in-depth analysis of corrugation profiles and flow dynamics.

- Constant testing for various condensing applications.

Having successfully manufactured and commissioned more than 2500 Corrugated Tube Heat Exchangers for various applications, we can trust this technology to replace Plain Tube Heat Exchangers.

This informative blog focuses on the advantages of KICC Corrugated Tube Heat Exchangers and their saving potential.

Key Elements:

- Use of corrugated tubes in heat exchanger technology

- The KICC Advantage

- How does it differ from conventional Heat Exchangers?

Corrugated tubes in heat exchanger: An Overview

It is an advanced technology set to revolutionize the way heat transfer takes place. The use of corrugation pattern on the tubes causes two flow regimes to the fluid in the tube, spiral at the core and eddy in the periphery, thus inducing turbulent flow even at low velocities. This results in a higher heat transfer coefficient. The corrugation pattern allows for drop-wise condensation, reducing the heat transfer area by 50% for same application. Thus, Corrugated Tube Heat Exchangers come in a far more compact design and provide a much more economical alternative to Shell and Tube Heat Exchangers for the same process.

Nearly 40 years of experience in this industry has helped Kinam Engineering to build robust models which extend its overall reliability. Its benefits make it a preferred equipment which is ideal for various industries like Chemicals & Petrochemicals, Fertilizers, Refineries, Pharmaceuticals, Biotech, Edible Oil, Paper, Steel, Cosmetics, and Textiles.

Benefits at a glance

Take a look at the comparison chart to understand how KICC combines advantages of both Plate Heat Exchangers and Shell & Tube Heat Exchangers,

Having its own technology has given a head start to Kinam Engineering to cater to multiple clients across various industries.

We solicit enquiries for specific requirements. Our skilled engineers offer solutions tailor-made to customer specifications. Kinam Engineering has been in the Heat Exchanger business for 40 years and caters to global clients with a proprietary product portfolio.

We hope you enjoyed reading this blog and learned a great deal about Corrugated Tube Heat Exchangers. Next in line, we will share the advantages that KICC has over conventional Shell and Tube Heat Exchangers.