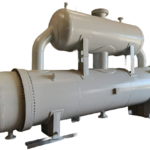

‘U’ Tube Type -

Shell & Tube Heat Exchanger

U tube type shell & tube heat exchanger

The simple design of a shell and tube heat exchanger makes it an excellent cooling solution for a wide range of applications. One of its most common uses is to cool hydraulic fluid and oil in engines, transmissions, and hydraulic power packs. With the appropriate choice of materials, it can also be utilized to cool or heat other substances, such as swimming pool water or charge air. A major advantage of using a shell and tube heat exchanger is that they are often easy to service and maintain, especially when equipped with a floating tube bundle (where the tube plates are not welded to the outer shell). They can also be employed in fixed tube sheet heat exchangers.

The tube bundle has the ability to expand or contract freely, eliminating any thermal stress caused by temperature differences between the tube and shell. This results in excellent thermal compensation performance.

The structure of this heat exchanger is simple, consisting of only one tubesheet and a smaller sealing surface, which makes it more affordable.

Cleaning and maintenance of the u tube heat exchanger are easy because the tube bundle can be easily removed from the shell body.

This type of heat exchanger is lightweight and well-suited for high temperature and high pressure environments.