Shell and Tube

Heat Exchanger

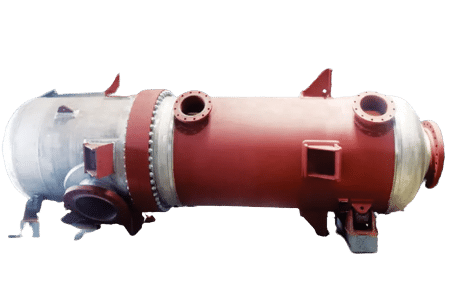

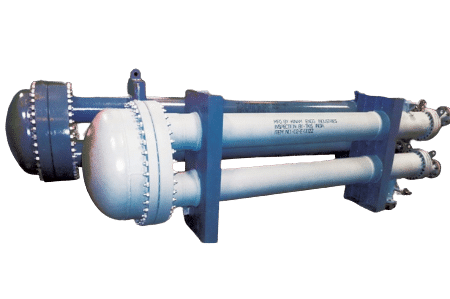

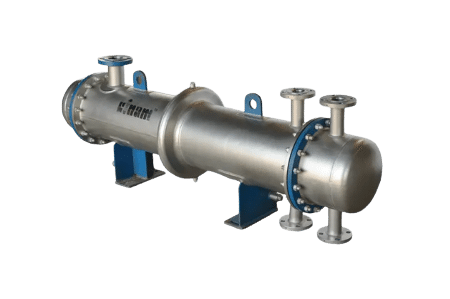

Shell and Tube Heat Exchanger

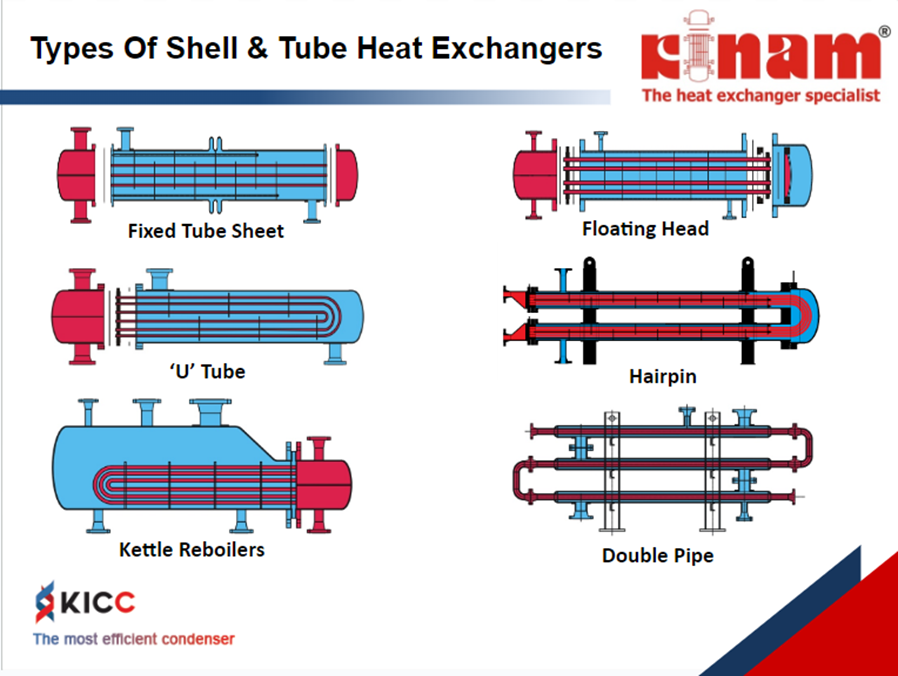

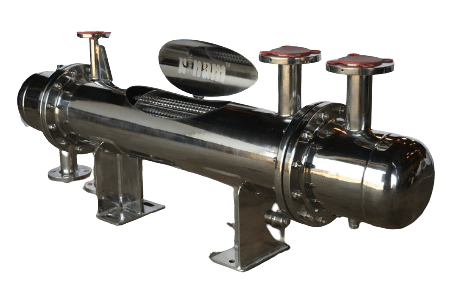

A shell and tube heat exchanger is a type of heat exchanger that consists of a cylindrical shell (also known as a housing) and a bundle of tubes inside it. It is designed to facilitate efficient heat transfer between two fluids while keeping them physically separated.

The shell is a large, robust vessel that encloses the tube bundle. The shell also has inlet and outlet ports for the entry and exit of the fluids.

The tube bundle is composed of multiple tubes, which are usually made of materials that provide good thermal conductivity, such as stainless steel, Titanium, Hastelloy, Inconel, Monel, Nickel 200, Duplex, Super Duplex, Cu-Ni alloys. The tubes can be arranged in various configurations, including parallel, U-shaped, or helical designs. The choice of tube arrangement depends on factors such as the desired heat transfer efficiency, flow rates, and space limitations.

One fluid, often referred to as the process fluid or the primary fluid, flows through the tubes. This fluid can be either a gas or a liquid and can be hot or cold depending on the specific application. The other fluid, known as the service fluid or the secondary fluid, flows through the shell surrounding the tube bundle. This fluid is typically used to either heat up or cool down the process fluid, depending on the heat exchange requirements.

During operation, the two fluids pass on opposite sides of the tube walls, creating a temperature gradient. Heat is transferred from the hotter fluid (process fluid) to the colder fluid (service fluid) through the tube walls via conduction. The large surface area provided by the numerous tubes facilitates efficient heat transfer between the two fluids.

Shell and tube heat exchangers are widely used in various industries due to their versatility, reliability, and efficiency. They are commonly found in applications such as power generation, chemical processing, oil refining, HVAC systems, refrigeration, and many other thermal processes.

Shell diameter: 4000 mm

Shell thickness: 25 mm

Overall length: 25 m

Tubesheet thickness: 400 mm

Max pressure : 200 kg/cm2

Heat transfer area: 1 m2 to 4000 m2

Max weight: 100 tonnes3

Austenitic Stainless Steel (All 300 series)/ Carbon Steel/ Alloy Steel/ Hastelloy/ Inconel/ Monel/ Nickel 200/ Cu-Ni Alloys/ Titanium/ Duplex/ Super Duplex

ASME boiler & Pressure Vessel Code/ TEMA/ EN 13445 & AD 2000 under PED with CE marking

Our Products

We have served multiple companies with our Heat Exchangers, and we are here to help you with our wide range of Heat Exchangers customized to meet your unique business requirements.

Contact Experts

Contact Experts

Have a heat exchanger need? We have a panel of experts who will help you in getting the best-suited

Heat Exchanger for your production requirement.