Revolutionizing Energy Efficiency with Advanced Heat Exchanger Designs

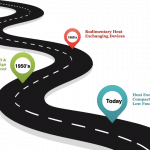

The world is at a crossroads, facing the daunting challenge of balancing economic growth with environmental sustainability. As industries continue to grow and expand, their energy consumption and greenhouse gas emissions have become a pressing concern. In this context, heat exchangers have emerged as a crucial component in the quest for sustainable industrial practices. But what exactly are heat exchangers, and how can advanced designs revolutionize energy efficiency?

The Role of Heat Exchangers in Industrial Energy Consumption

Heat exchangers are devices that facilitate the transfer of heat from one fluid to another, playing a vital role in various industrial processes, such as power generation, chemical processing, and HVAC systems. However, traditional heat exchanger designs often suffer from inefficiencies, leading to wasted energy and increased emissions. According to the U.S. Department of Energy, "Heat exchangers are a critical component in many industrial processes, and improving their efficiency can have a significant impact on energy consumption and greenhouse gas emissions."

Advances in Heat Exchanger Materials and Manufacturing Techniques

Recent breakthroughs in materials science and manufacturing techniques have paved the way for the development of advanced heat exchanger designs. For instance, the use of nanomaterials and 3D printing has enabled the creation of compact heat exchangers with enhanced thermal performance. As Dr. Yury Gogotsi, a leading researcher in nanomaterials, notes, "The unique properties of nanomaterials make them ideal for applications where high thermal conductivity and mechanical strength are required."

Innovative Designs for Enhanced Energy Efficiency

Several innovative heat exchanger designs have emerged in recent years, each with its unique advantages and applications. Some of the most promising designs include:

- Compact heat exchangers, which use advanced materials and geometries to minimize size and maximize thermal performance

- Plate heat exchangers, which employ a plate-and-frame design to facilitate efficient heat transfer

- Spiral heat exchangers, which utilize a spiral geometry to enhance fluid flow and heat transfer

These designs have been successfully implemented in various industries, resulting in significant energy savings and reduced emissions. For example, a study by the National Renewable Energy Laboratory found that compact heat exchangers can reduce energy consumption by up to 30% in certain industrial applications.

Real-World Applications of Advanced Heat Exchanger Designs

The benefits of advanced heat exchanger designs are not limited to theoretical simulations or laboratory experiments. Many industries have already adopted these innovative designs, with remarkable results. Some notable examples include:

- Power generation: Advanced heat exchangers have been used to improve the efficiency of power plants, reducing energy consumption and emissions.

- Chemical processing: Compact heat exchangers have been employed to enhance the thermal performance of chemical reactors, resulting in increased productivity and reduced waste.

- HVAC systems: Plate heat exchangers have been used to improve the efficiency of heating and cooling systems, leading to significant energy savings and reduced emissions.

Future Directions in Heat Exchanger Research and Development

As the demand for sustainable industrial practices continues to grow, researchers and engineers are exploring new frontiers in heat exchanger design. Some of the most promising areas of research include:

- Integration with renewable energy sources: Advanced heat exchangers can be used to enhance the efficiency of solar thermal systems and other renewable energy technologies.

- Advanced thermal energy storage systems: Innovative heat exchanger designs can be used to improve the performance of thermal energy storage systems, enabling more efficient energy storage and release.

Overcoming the Challenges of Implementing Advanced Heat Exchanger Designs

While advanced heat exchanger designs offer numerous benefits, their implementation can be hindered by several challenges, including:

- High upfront costs: The development and installation of advanced heat exchangers can be expensive, making them less attractive to industries with limited budgets.

- Complexity: Advanced heat exchanger designs often require sophisticated materials and manufacturing techniques, which can be difficult to integrate into existing industrial processes.

However, as the benefits of advanced heat exchanger designs become more widely recognized, industries are beginning to invest in these innovative technologies. As Dr. Gogotsi notes, "The development of advanced heat exchangers is a critical step towards sustainable industrial practices. While there are challenges to overcome, the potential benefits are too great to ignore."

Finding Inspiration in Unlikely Places

The pursuit of innovation in heat exchanger design can often lead to unexpected sources of inspiration. Just as the intricate patterns and geometries found in nature have influenced the development of advanced materials and manufacturing techniques, the world of gaming can also provide valuable insights into the importance of optimization and efficiency. Consider, for example, the complex algorithms and mathematical models that underlie the design of online games, such as those found at Deadwood R.I.P. These games require a delicate balance of risk and reward, with players constantly seeking to maximize their chances of success while minimizing their losses. Similarly, the design of advanced heat exchangers requires a deep understanding of the complex interplay between thermal performance, material selection, and manufacturing techniques. By embracing this kind of interdisciplinary thinking, engineers and researchers can unlock new and innovative solutions to the challenges of sustainable industrial practices.

Conclusion

Advanced heat exchanger designs have the potential to revolutionize energy efficiency and sustainability in various industries. By leveraging innovative materials and manufacturing techniques, these designs can significantly reduce energy consumption and greenhouse gas emissions. As the world continues to grapple with the challenges of climate change and sustainable development, the importance of advanced heat exchanger designs will only continue to grow.

Some of the key factors to consider when selecting an advanced heat exchanger design include:

- Thermal performance: The ability of the heat exchanger to efficiently transfer heat between fluids.

- Material selection: The choice of materials can significantly impact the thermal performance and durability of the heat exchanger.

- Manufacturing techniques: Advanced manufacturing techniques, such as 3D printing, can enable the creation of complex geometries and structures.

- Cost and complexity: The upfront costs and complexity of the heat exchanger design can impact its adoption and implementation.

By carefully considering these factors, industries can select advanced heat exchanger designs that meet their specific needs and goals, ultimately contributing to a more sustainable and energy-efficient future.