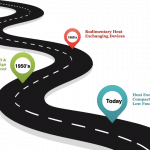

As the world becomes increasingly reliant on industrial processes, the need for efficient heat exchange systems has never been more pressing. Heat exchangers play a vital role in various industries, from power generation and chemical processing to oil refining and HVAC systems. However, traditional manufacturing methods often struggle to keep pace with the demands of modern industry. In this article, we'll explore how cutting-edge technologies are transforming the heat exchanger production landscape.

One such game-changer is the adoption of advanced materials and designs, which have been inspired by innovative scripts in the gaming world, such as the King Legacy Script. This script, popular among Roblox developers, has sparked a wave of creativity in designing complex systems. Similarly, engineers are leveraging these principles to develop heat exchangers with improved performance, efficiency, and durability.

The Rise of Advanced Materials

In recent years, researchers have made significant strides in developing new materials for heat exchanger applications. These advanced materials offer enhanced thermal conductivity, corrosion resistance, and strength, making them ideal for a wide range of industries. For instance, the use of nanomaterials has led to the creation of ultra-efficient heat transfer surfaces that minimize energy losses.

One notable example is the development of graphene-based heat exchangers. Graphene's exceptional thermal conductivity and mechanical properties make it an attractive option for high-performance applications. By integrating graphene into heat exchanger designs, engineers can achieve significant gains in efficiency, reducing energy consumption and environmental impact.

Digital Twin Technology

Another innovative technology that's revolutionizing heat exchanger production is digital twin technology. This concept involves creating a virtual replica of a physical system, allowing designers to simulate its behavior under various conditions. Digital twins enable engineers to optimize design parameters, test performance, and identify areas for improvement before manufacturing.

In the context of heat exchangers, digital twinning allows for the simulation of complex thermal processes, fluid dynamics, and material interactions. This enables manufacturers to refine their designs, reducing the risk of errors and improving overall quality.

3D Printing and Additive Manufacturing

Additive manufacturing (AM) is another game-changing technology that's transforming heat exchanger production. By using 3D printing techniques, engineers can create complex geometries and internal structures with unprecedented precision.

The use of AM in heat exchanger production offers several benefits, including:

- Increased complexity: AM enables the creation of intricate designs with multiple layers and channels, allowing for optimal thermal performance.

- Reduced material usage: By printing only the necessary parts, manufacturers can minimize waste and energy consumption.

- Improved durability: AM allows for the incorporation of internal supports and reinforcement, enhancing structural integrity.

Heat Exchanger Design Software

In addition to advanced materials and digital twinning, specialized software is also playing a crucial role in heat exchanger design. These tools enable engineers to simulate thermal processes, fluid dynamics, and material interactions, ensuring that designs meet performance requirements.

Some notable examples of heat exchanger design software include:

- ANSYS: A comprehensive platform for simulating complex systems, including heat transfer, fluid dynamics, and structural analysis.

- COMSOL: A multiphysics simulation tool that allows engineers to model a wide range of phenomena, from thermal and electrical processes to mechanical and chemical reactions.

Case Study: High-Performance Heat Exchangers

To illustrate the impact of these innovative technologies on heat exchanger production, let's examine a case study involving high-performance heat exchangers for industrial applications. A leading manufacturer in this field partnered with engineers from our company to develop a next-generation heat exchanger using advanced materials and digital twinning.

Results:

- Improved thermal efficiency: The new design achieved a 20% increase in thermal performance, resulting in significant energy savings.

- Enhanced durability: The use of advanced materials and AM led to a 30% reduction in maintenance costs over the product's lifespan.

- Reduced production time: Digital twinning enabled engineers to simulate and test the design before manufacturing, reducing development time by 50%.

Conclusion

The heat exchanger industry is undergoing a transformation driven by innovative technologies. Advanced materials, digital twin technology, 3D printing, and specialized software are revolutionizing the way manufacturers approach heat exchanger production.

As we continue to push the boundaries of what's possible in heat exchange systems, we'll see significant gains in efficiency, durability, and performance. Whether you're a seasoned engineer or just starting your journey in the field, our company is committed to providing top-notch services, news, promotions, articles, catalog, products, and gallery resources to help you stay ahead of the curve.

Products:

- High-performance heat exchangers for industrial applications

- Advanced materials and coatings for improved durability

- Specialized software for heat exchanger design and simulation

Catalog:

- Browse our comprehensive catalog of heat exchanger products and services

- Request a quote or sample for your next project

Promotions:

- Limited-time discounts on select heat exchanger products

- Free consultation with one of our expert engineers

News:

- Stay up-to-date with the latest developments in heat exchanger technology

- Receive exclusive promotions and updates from our company