How Heat Exchangers have evolved through time:

Introduction:

Heat Exchangers on their own can drastically reduce fuel consumption, cut costs and reduce the carbon footprint making them an integral part of any production plant. Heat Exchangers can affect the plant’s overall efficiency, and as industries grow, the need for more efficient and improved heat exchangers is on a constant rise. As such, it is thus imperative that we learn about the history of these devices, and how they have developed over the years.

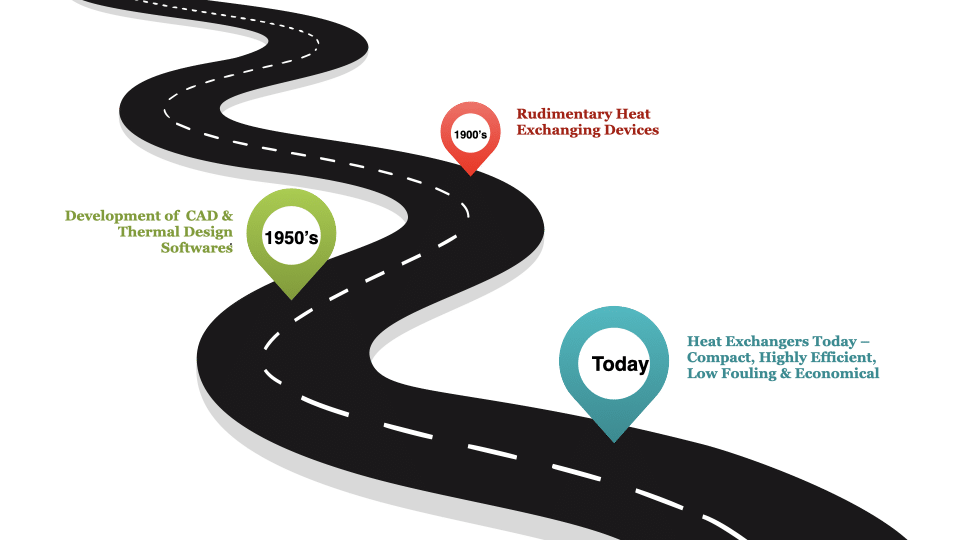

Rudimentary examples of heat exchanging devices have been found in Europe from Roman Times, where systems we would now call recuperators were used in baths. Around the turn of the first millennium, the principles for indirect heat exchange were being used for the production of pure alcohol, which still are the core principles of Heat Exchangers.

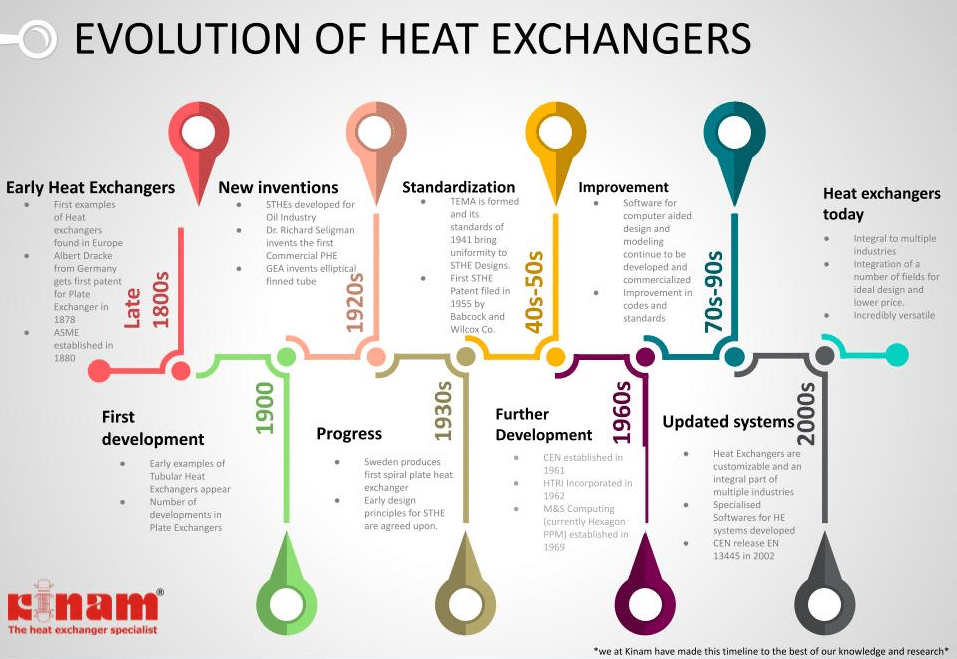

The recorded history of Heat Exchangers can be traced around the 1880s, their major applications being the food and beverage industries. It is widely recognized that the first recorded patent for a Plate heat exchanger was awarded to Albrecht Dracke of Germany in 1878. However, the first modern and commercial examples of Heat Exchangers would be observed in the early 1900s.

Initial developments In the early 1900s:

In the early 1900s, the first known designs for Tubular Heat Exchangers were developed. These were developed due to the operational demands from power plants, where they would be used as condensers as well as feedwater heaters, both of which are still common applications. Between the late 1880s and 1920s, several developments were made for Plate Heat Exchangers (PHE), which resulted in many patents covering its different forms, particularly its use in the pasteurization of milk.

HE technology during the 1920s & 30s:

Initial designs of Shell and Tube Heat Exchangers (STHE) were developed during the 1920s for emerging uses in the oil industry. They were applied as oil heaters/coolers, reboilers, and condensers in crude oil plants. They also found applications that operated in rough environments or at high pressures and pressures. However very little was known about tubular heat exchangers design. Most designs were made considering material strength, while heat transfer was crudely measured from estimates.

Gesellschaft für Entstaubungs-Anlagen mbH (GEA) was founded in Feb 1920 in the heart of Ruhr, one of Germany’s most important industrial centers at the time, with coal mining and steel production being the main industries. Under the leadership of the company’s founder Otto Happel, the company’s first new product–a closed-circuit air cooling system that used air circulating in a metal tube built around the electrical engine–was developed for large electrical machinery. Happel pioneered this technology in collaboration with Professor Ludwig Prandtl, director of the Aerodynamic Research Institute in Göttingen, and together they invented a new air-cooling device: the elliptical finned tube.

In 1923, Dr. Richard Seligman ( who established the Aluminum Plant & Vessel Company in 1910) invented the first commercially viable PHEfor applications in breweries and vegetable oil industries. The PHE revolutionized methods of indirect heating and cooling of fluids.

In the early ’30s, Sweden produced the first Spiral plate heat exchanger and would go on to produce the first plate-shell heat exchanger for use in pulp mills later in the decade. The UK also started the use of the brazing method to create a plate-fin heat exchanger made of copper and copper alloy materials for applications in aircraft engines.

In 1935, Otto Happel and German engineer Dr. Kurt Lang started working on air-cooled condensers for stationary steam turbines used for electricity generation, and in 1939, GEA commissioned the first pilot project using an air-cooled condenser for stationary steam turbines at the Waltrop Colliery in Ruhr, Germany. After initial doubts, Hample and his team further developed the technology, which would turn out to be successful in the coming decades for GEA.

That being said, the heat exchangers made for water-water and water-steam applications during the 1920/the 30s are comparable to their modern-day counterparts, due to the overpowering effect of fouling. Standardizations for STHE would be set in place in the coming decade. In 1938, Alfa-Laval introduced its first heat exchanger.

While design principles for STHE were also agreed upon by designers from data and educated assumptions during this period, a lot of technical factors of tubular heat exchangers were still unknown and most data collected was from trial and error. That being said, the heat exchangers made for water-water and water-steam applications during the 1920/the 30s are comparable to their modern-day counterparts, due to the overpowering effect of fouling. Standardizations for STHE would be set in place in the coming decade. In 1938, Alfa-Laval introduced its first heat exchanger.

Further improvements:

As time went on, heat exchangers started being made with new materials to accommodate more corrosive media. STHE type heat exchangers made significant strides during the 1940s. Designers started understanding shell side pressure drop during this period. Tubular Exchanger Manufacturers Association (TEMA) standards of 1941 brought much-needed uniformity in STHE designs, which till now were tightly guarded secrets of the manufacturer.

Babcock and Wilcox Co. with inventor Johannes H Ammon filed the Patent for Shell and Tube Heat Exchanger on 17th March 1955. The patent was granted almost a decade later on 02nd February 1965 and expired on 02nd February 1982. Link to the patent

Improvements would continue to be made through the 60s with a better understanding of viscous flow. Plate exchangers were first introduced to the oil and gas industry during this time. The 60s also saw rapid development in the fields of space technology, industrial activity, and sciences, combined with improved developments in production techniques Heat Exchanger manufacturing improved and covered a variety of applications and size requirements.

Developments In Software:

Computer-Aided Design (CAD) software began developing in the late 1950s, with the common consensus being that ‘Sketchpad’ by Ivan Sutherland was the first true CAD software. Sutherland developed Sketchpad in the early 1960s as a part of his Ph.D. thesis at MIT. Industries slowly started to move to the use of CAD software to mechanically design Heat Exchangers. Incorporated in 1962, HTRI was chartered to conduct application-oriented research in the field of heat transfer and fluid flow technology. HTRI today is one of the most trusted research institutions in the world, and their software has helped design several heat exchangers.

M&S Computing (Currently Hexagon PPM) was formed in Alabama, USA in 1969. They developed the first interactive CAD product, Interactive Graphics Design Software (IGDS), which became an industry benchmark in a very short period. They went on to develop PV Elite, one of the most known mechanical design software today.

Thermal designs and modeling had a slower start, with the first commercial use of computational software starting in the 1970s. While research remained a top priority, through the 1990s it became apparent to multiple industries that the use of computers to design, model and simulate was the norm. The coming decades saw multiple strides made in software designed specifically for Heat Exchangers as HTRI Xchanger Suite.

Development in Code and Standards:

TEMA was founded in 1939 as an association of STHE fabricators to bring uniformity in STHE designs, and ‘The TEMA Standards’ (currently in its 10th edition) is still considered as the standard to follow for STHE design across the industry. (Disclaimer: as per information available in a public domain) TEMA Standards have 3 subcategories, Class R for petroleum and refineries, Class C for general commercial use, and Class B for chemical process service. Class C is the least stringent class, while Class R is the most. TEMA standardizes the nomenclature of exchanger types, by giving a letter designation. Eg. A kettle-type reboiler with a removable U-tube bundle is a ‘BKU’ type.

The American Society of Mechanical Engineers or ASME was established in 1880. ASME has codes and standards for various technical areas and components. ASME has over 110,000 members in more than 150 countries worldwide. The ASME Boiler and Pressure Vessel Code (BPVC) is its largest standard in both size and number of volunteers. Its main objective was to prevent the failure of boiler pressure vessels. The ASME VIII code refers to the pressurized parts of a shell and tube heat exchanger, which covers the parts inside the shell, primarily tubes. Sections II and V, which refer to materials and non-destructive testing, are also occasionally used for design purposes.

The CEN (French for Comité Européen de Normalisation) also known as the European Committee for Standardization, is a public standardization group established in 1961. Its 34 member nations work together to develop European Standards (ENs) across various sectors/services and are officially recognized as a European standards body by the European Union, European Free Trade Association, and the United Kingdom. EN 13445, a relatively new pressure vessel code came into full effect on May 22, 2002. Written with the European Pressure Equipment Directive, it was put together over 10 years by CEN Technical Committee TC54. While it doesn’t have a strong historical background and has the disadvantage of ‘lowest common denominator writing, it was written by experts who are responsible for maintaining the various national codes and is intended to update regularly to bridge existing gaps.

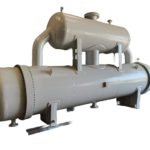

Heat Exchangers Today:

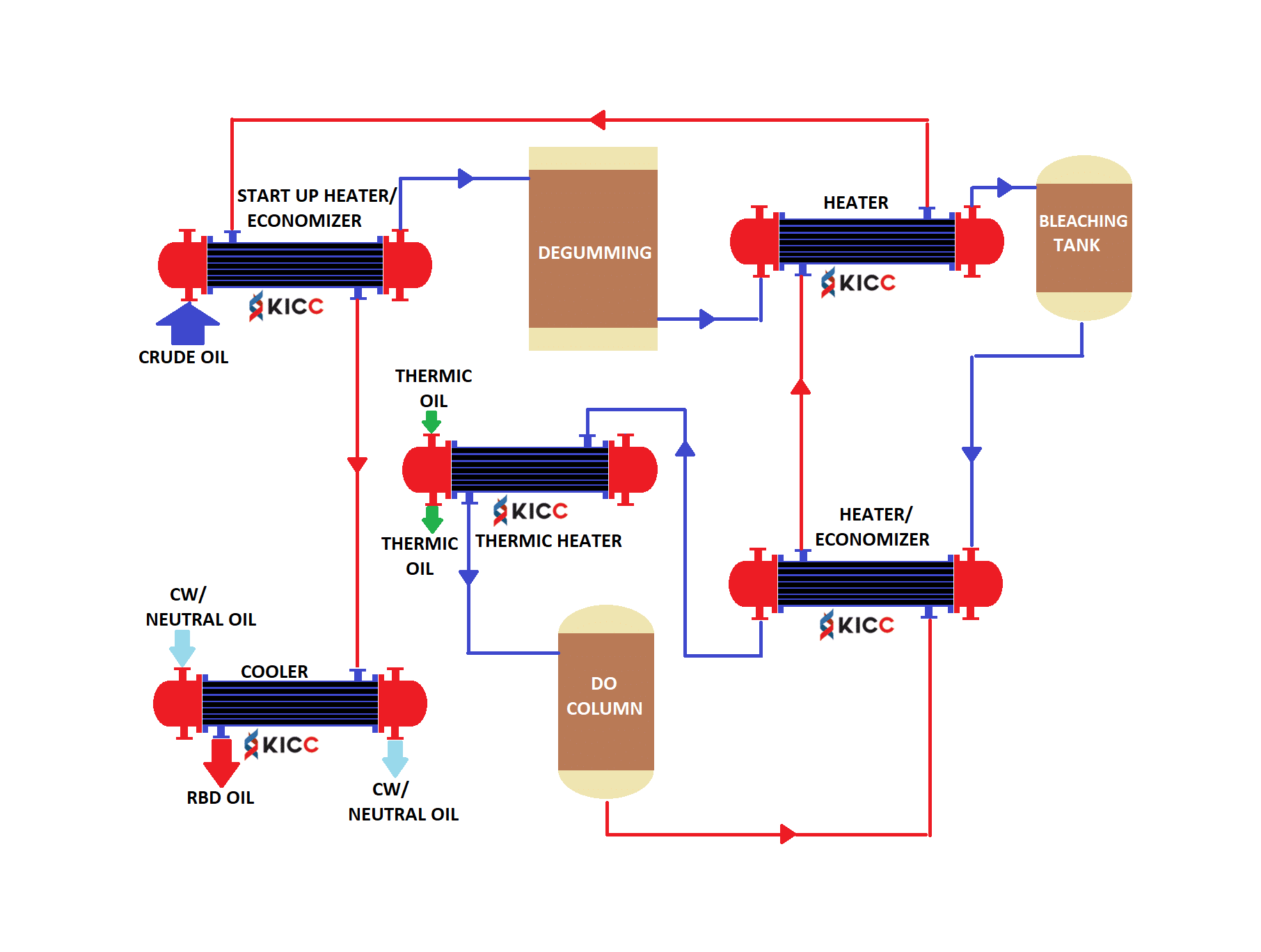

Example of today’s Heat Exchanger systems in use in an Edible Oil Industry

Heat exchangers are a part of almost every industry, including but not limited to chemical, petrochemical, pharmaceutical, fertilizer, agrochemical, paint, metal, paper, Edible oil, etc. While the principles of these heat exchangers haven’t changed, improvement in fluid circulation/flow control, digital designing and simulation tools, material technology, fabrication methods, and means to easily integrate all these factors have resulted in versatile, highly efficient heat exchangers at much lower costs.

With customized solutions now easier than ever, proper application of modern exchangers can considerably improve the heat recovery efficiency, reusing 35-60% of the heat generated. One of the modern-day examples of Heat Exchangers is Kinam’s KICC series, but more on it later. (In our upcoming blog)

References : Araner | Norenthermal.com | Hedhme.com | Foodprocessinghistory | Google Patents | SRP | Jfiflow | Thermopedia.com | IBPSA | Enerquip | Americanheatingco | Cencenelec | Wermac |