How Kinam helped a Chemical company save 30% on its Heat Transfer Budget

Short Summary:

A 2500 TPA Synthetic Organic Chemical Manufacturing Plan for Speciality Intermediates was entering the procurement phase, and the team at this Maharashtra based chemical manufacturer wanted more than just a Heat Exchanger Provider for this project, they wanted someone who knows the craft and could help in the Process Designing.

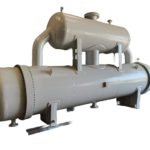

Once designing of the proprietary process primarily involving solvents for a greenfield project was complete , their search for a partner that could successfully design & supply 49 Heat Exchangers to fit a wide range of requirements that included applications like Solvent Condensers, Reboilers, Overhead Condensers, and Sub-coolers, all used in the distillation process started.

Although we hadn’t worked together up to that point, Kinam was in contact with the company for over a year and had built a rapport with them. When they eventually had an order, they shared their design requirements with us, as well as other vendors to submit designs and quotes.

Our team of Process Designers worked extensively on the brief and in 3 months of working with the chemical manufacturers’ technical team, were successfully able to get their seal of approval on the design. It was a moment of pride when we made their team extremely happy and scored Technical approvals on all 49 Designs.

From never having worked together before to handing their entire order, this case study will cover how our design team helped adopt new technology for a new start of their plant.

Problem Statement:

For their plant’s proprietary distillation process, the initial idea was to implement Shell and Tube Heat exchangers. They needed a vendor that could do the complete thermal and mechanical design of the various heat exchangers required.

The requirement was for a total of 49 heat exchangers for a number of applications, have different spatial restrictions, and also included special hammerhead condensers. These would be carrying a number of fluids including Methanol, Low-Pressure Steam, Water, organic vapors & liquids, Brine, etc. Each of these exchanges would run under full vacuum conditions, so all process flanges had to be provided with tongue and groove Flanges.

The Solution:

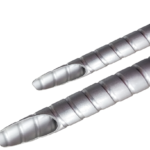

While the initial demand was for Shell and Tube Exchangers, having designed similar condensers for clients in the past, our design team was sure that the implementation of KICC Corrugated Tube Heat Exchangers would be a more efficient solution for them. Adopting new technology is usually met with resistance, this time to it was the same case. The resistance was obvious, betting on new technology for such a huge project is not an easy decision to make. Our sales and design experts stepped in and soon from betting on new technology we were able to help them take a leap to be able to have trust in the new technology. At Kinam we understand that trusting the process is as important as its benefits.

The execution of this project required an experienced team, especially for the design of HammerHead condensers, and our designers were up to the challenge. After receiving the process conditions and parameters, with the help of an extremely supportive team of the chemical company, together we arrived at designs best suited for their process requirements. Our Client was thoroughly impressed by how technically sound the designs were. Complete trust in our designs was a major reason why they let us handle the entire order of 49 exchangers.

Benefits:

While the client initially wanted Shell and Tube Heat Exchangers, by implementing Kinams KICC Corrugated Tube Heat Exchangers, we were able to reduce their initial capital investment by 30%*. With a higher heat transfer coefficient than regular Shell and Tube Heat exchangers. KICC Tube Heat Exchangers were a more compact and economical alternative. Moreover, the Intermediate manufacturer will also enjoy the expected benefits of Corrugated Tube Heat Exchangers like

- Reduced Downtime

- Lower Maintenance

- Lower Fouling

- Higher Condensation Rate

KICC Heat Exchangers are the best available technology in the Heat Transfer Market when it comes to condensing applications allowing maximum recovery of solvents, which saves them the cost of expensive solvent loss and is better for the environment as well.

Numbers Game:

| Number of Heat Exchangers Supplied | 49 |

| Type of Tube | Corrugated |

| Total Handling Weight of the project | 80 Tonnes* |

| Total number of tube length in meters | 19000 M |

| Area Range | 3m2 to 120m2 |

| Construction Material | Complete SS316 |

| Mechanical design done as per ASME Section 8 div 1 & TEMA Standards, Welding as per ISO 3834- 2 | |