Why are spiral heat exchangers the best economizers for Palm Oil refineries?

Kinam Engineering Spiral Heat Exchanger designs for profits

Heat exchangers play a key role in minimizing varied costs in edible oil refineries. They are the ideal economizers to recover heat and prevent losses. These machines are in demand in South East Asia where palm oil is processed in large volumes. Spiral heat exchangers are considered apt for oil heating and cooling functions.

Kinam Engineering, India devises edible oil heat exchanger designs for the global markets dealing in refined palm oil. Our spiral heat exchangers directly benefit the performance and contribute to profitability for plant owners.

Kinam Engineering continues to be the preferred vendor for several kinds of heat exchangers worldwide for the last 40 years. We present the overall benefits of our spiral heat exchangers specifically designed as economizers for the palm oil industry.

Understanding the need for Palm oil heaters

Although Palm oil is a very popular edible oil used across the world, it is a high risk commodity unless processed correctly. As a food-grade staple, it is found in many products in the market. It is a stable oil and has fewer trans fatty acids. This is the perfect alternative to animal products and fatty hydrogenated oils.

Currently, close to 90% of Palm oil is produced in Indonesia and Malaysia. Indonesia produces nearly 35 million tons each year

Palm Oil Processing Unit Operations

The Refining Process:

There are various processes at different stages in which oil is heated and cooled. It depends on the type of oil and its characteristics which are being handled.

Palm oil comes into the industry at a normal atmospheric temperature in a vessel. During the first stage of degumming, the gum and phospholipids are removed from the oil. The process is carried out at 90 to 100 degrees c. Then comes neutralization to get rid of acid used for degumming done at 130-150 degrees c. At this point caustic and water is added to neutralize the acid content, after which soap and fatty acids are removed.

Oil is now washed at 150 degrees c. Water is removed which completes the drying process. Winterization comes next to remove excess wax from the oil. The bleaching process follows and is performed at an elevated temperature of 125 degrees c. Deodorization process is the last stage done at 250-260 degrees. After this stage, oil is ready for packaging. However, at a high temperature it cannot be packed. It needs to be cooled.

Why is an economizer required for palm oil refineries?

During the palm oil refining process, the oil is heated and cooled at various stages. When the oil is cooled, there is a considerable loss of heat energy. This energy is recoverable and can be used in another refining stage where heating is required. Waste heat energy is recovered by exchanging said heat with the incoming oil.

To recover this high amount of energy, heat exchangers are used as economizers. Using the otherwise waste heat energy, an economizer is able to increase thermal efficiency by decreasing the energy required to heat the incoming oil, saving fuel and hence reducing the costs.

Why are Spiral Heat Exchangers preferred?

The main advantage of using spiral heat exchangers as economizers is the amount of heat they can recover.

Spiral HEs are circular units containing two concentric spiral flow channels, one for each fluid. One fluid enters the center of the unit and flows towards the periphery whereas the other fluid enters the unit at the periphery and moves towards the center. As a result, the equipment gives a 100% counter-current flow, thus providing higher heat transfer rates.

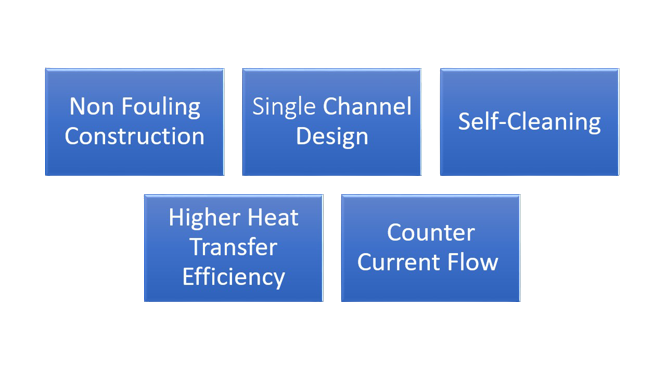

With studs and curvature of the single-channel promoting turbulent flow, Spiral Heat Exchangers like the K-SPEX can give twice the heat transfer coefficient when compared to Shell and Tube, recovering up to 90% of heat with a 2-degree approach. This makes it a good bet to be used as an economizer.

A high heat transfer rate also allows Spiral Heat Exchangers to be more compact in terms of area and volume, another advantage they have over traditional Heat Exchangers.

Palm Oil economizers play a big role in every stage of the refining process. Investing in the right kind of spiral heat exchanger makes all the difference. Kinam Engineering is making strides in this sector with its K-SPEX Spiral Heat Exchangers specifically designed for active palm oil processing. Spiral Heat Exchangers have the following advantages that make them perfect for use as economizers:

Let’s talk about your needs if you are in the business of palm oil processing. We can make an exclusive spiral heat exchanger for your plant.